Steps for correctly installing the planetary gearbox

Release Time:

Mar 28,2024

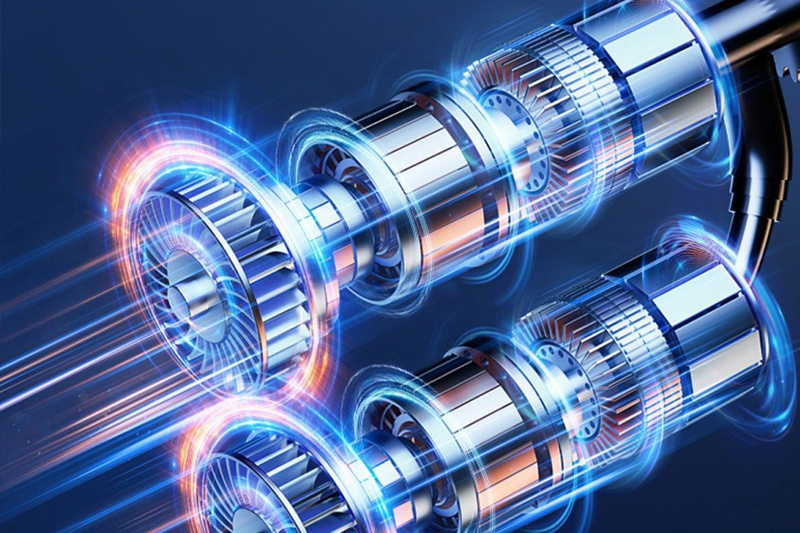

Planetary reducer, by its name, we can know that planetary reducer is mainly used for deceleration. So, what equipment does planetary reducer help with deceleration? It is mainly used to reduce one speed of the motor, thereby increasing the output torque. Therefore, many industries in our lives use planetary reducers, but for some first-time users, they may not know how to install them when they first receive them. Therefore, today, we will provide a detailed introduction to the installation steps of precision planetary reducers.

Planetary reducer, by its name, we can know that planetary reducer is mainly used for deceleration. So, what equipment does planetary reducer help with deceleration? It is mainly used to reduce one speed of the motor, thereby increasing the output torque. Therefore, many industries in our lives use planetary reducers, but for some first-time users, they may not know how to install them when they first receive them. Therefore, today, we will provide a detailed introduction to the installation steps of precision planetary reducers.

Firstly, before installation, confirm whether the motor and reducer are intact and strictly check whether the dimensions of the various parts connected to the motor and reducer match. Here are the dimensions and fitting tolerances of the positioning boss, input shaft, and reducer groove of the motor.

Secondly, unscrew the screw on the outer dust hole of the reducer flange, adjust the PCS system clamping ring to align its side hole with the dust hole, and insert the inner hexagon to tighten.

Step 3 of installation: Hold the drive motor in hand, align the keyway on its shaft with the screw that holds the input hole of the reducer, and insert the drive motor shaft into the input hole of the reducer. When piercing, ensure that the concentricity of both is parallel to the flange on both sides. It is necessary to determine the reason for the divergence of mindfulness or the non parallelism of the two flanges. Furthermore, it is strictly prohibited to use hammering during equipment operation, as it can prevent excessive axial or radial force from damaging the bearings of both, and distinguish whether the cooperation between the two is suitable based on the feel of the equipment. The method to distinguish between the concentricity of collaboration between the two and the parallelism of the flange is: after the two are penetrated into each other, the flange roots of the two are tightly attached, and the gaps are the same.

Additionally, during installation, it is strictly prohibited to use hammers or other tools to prevent excessive axial or radial forces from damaging bearings or gears. Be sure to tighten the installation bolts before tightening the tension bolts. Before installation, wipe the anti rust oil on the motor input shaft, positioning boss, and reducer connection with gasoline or zinc sodium water. Its purpose is to ensure the tightness of the connection and the flexibility of operation, and to prevent unnecessary wear. Before connecting the motor to the reducer, please make sure that the motor shaft keyway is perpendicular to the tightening bolt. To ensure even force distribution, please first screw on the installation bolts at any diagonal position, but do not tighten them, and then screw on the installation bolts at the other two diagonal positions. Finally, tighten the tightening bolts. All tightening bolts need to be fixed and inspected using a torque wrench according to the indicated fixed torque data.

What Else Might You Learn?