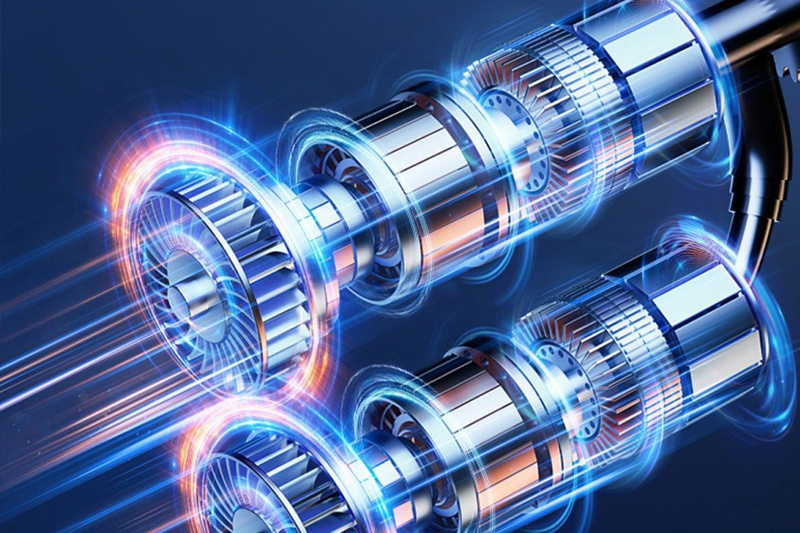

Gear reducer service process

Release Time:

Jan 10,2022

Purpose of gear reducer service: To provide various installation and inspection standards for gearbox maintenance personnel, improve the maintenance steps of the gearbox, ensure the quality of gearbox maintenance and upkeep, further improve the actual operating standards of this position, and develop operating procedures.

Purpose of gear reducer service:

To provide various installation and inspection standards for gearbox maintenance personnel, improve the maintenance steps of the gearbox, ensure the quality of gearbox maintenance and upkeep, further improve the actual operating standards of this position, and develop operating procedures.

1、 Preliminary preparation:

1. Based on the operation of mechanical equipment, clearly propose equipment maintenance and repair applications, and submit them to the company leadership for approval;

2. The maintenance personnel of the organization should inquire about the situation of the mechanical equipment on site, understand the current defects of the mechanical equipment from the operators, and make detailed records;

3. Gradually analyze mechanical equipment defects, predict new maintenance projects, and basically clarify maintenance plans;

4. Benefit the leadership cadres of the unit with the basic plan and discuss and clarify the basic plan;

5. Prepare relevant engineering drawings and materials in advance, purchase expected replacement parts, and track delivery progress;

6. Notify the manufacturer, discuss and specify downtime;

7. The division of responsibilities within the maintenance and upkeep work group, optimization of new maintenance projects, and clarification of responsible persons;

2、 Gradual maintenance:

1. Dismantling, gradually disassembling and assembling according to the structure of the mechanical equipment, and keeping detailed records to avoid parts confusion;

2. Clean the gearbox housing and check for any oil leakage points;

3. Inspect and measure the gears of the reducer, with a focus on checking the wear and meshing of the gears, and record the inspection results;

4. Measure the bearing clearance and check the wear condition, measure the housing and check the wear condition, and record various inspection results;

5. Measure the input, output, and intermediate shaft of the reducer, check the wear condition, and record the inspection results;

6. Summarize the above inspection results, summarize various specification errors, and clearly restore new projects;

What Else Might You Learn?