The story behind precision reducers

Release Time:

Mar 28,2024

The advanced level of industrial robots nowadays is breathtaking, especially those agile 5-axis 6-axis robots, which have so many joints and can achieve precise transmission of motion and commands. The various parts work closely together to complete complex tasks, making people curious about their transmission systems. Do you make them? The precision reducers used in the joints of robots worldwide are almost all made in Japan: the Japanese say kneeling, and few robots in the world can stand...

The advanced level of industrial robots nowadays is breathtaking, especially those agile 5-axis 6-axis robots, which have so many joints and can achieve precise transmission of motion and commands. The various parts work closely together to complete complex tasks, making people curious about their transmission systems. Do you make them? The precision reducers used in the joints of robots worldwide are almost all made in Japan: the Japanese say kneeling, and few robots in the world can stand...

In science fiction illustrations, robot joint processing has always been crucial. In the 1970s, the biggest difference between Japanese illustrator Konoyama Ki's beautiful robot and humans, apart from skin, was the addition of a large screw at the joint, which, upon closer examination, was not feasible.

In recent years, on some robots powered by human models, obvious segmentation and mechanical structures at the joints can be observed, which seems to be much more reliable.

So, what is the structure of the joints in real industrial robots?

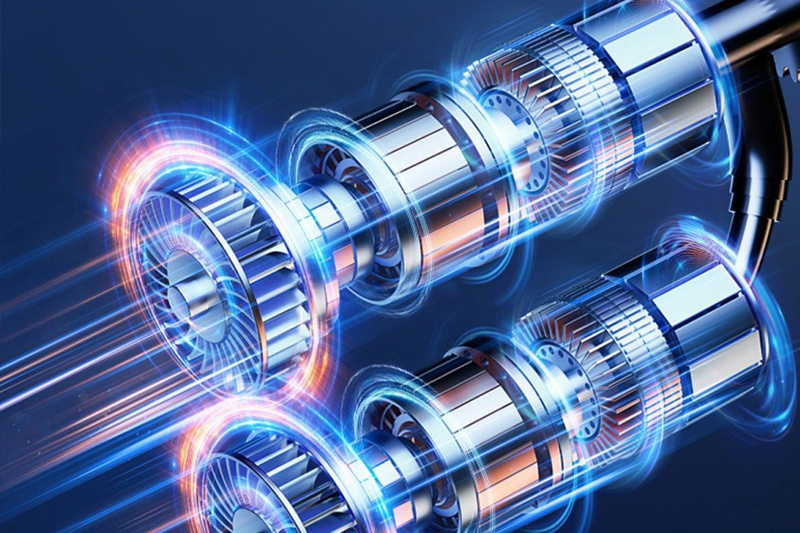

When it comes to joints, they mainly refer to the most important basic components of industrial robots, as well as the core components of motion: precision reducers. This is a precise power transmission mechanism that utilizes a speed converter of gears to reduce the motor's rotation to the desired number of rotations and obtain a device with a higher torque, thereby reducing the speed and increasing the torque.

Harmonic drive reducer

Harmonic gear drive is a gear transmission system that uses a wave generator to generate controllable elastic deformation of flexible gears and mesh with rigid gears, transmitting motion and power from the beginning. The harmonic drive reducer was invented by American Clarence Walton Musser (1909-1998-06-08) in 1957 (US Patent No. 2906143). In addition, this long-lived inventor who had worked at the US Department of Defense for 15 years had 250 major inventions throughout his life, such as military recoilless rifles, aircraft catapults, underwater explosion testing instruments, and so on.

It sounds like a larger industry category, but in fact, harmonic drive is a trademark of Harmonic Drive Systems Inc. In 1960, USM successfully put harmonic drive reducers into use for the first time, and later Hasegawa Gear Works, Ltd. obtained a production license from USM. In October 1970, Hasegawa and USM each contributed 50% to establish Harmonic Drive Systems Inc. in Tokyo, which is translated as Hammernac. Eight hexagrams: The then president of Hasegawa was named Tanegawa Gear Car, and the mechanical lord believed that this name was destined to be used for making gears...

Hammernac is a leading enterprise in overall motion control. Its HarmonicDrive combination harmonic reducer has the characteristics of lightweight, small size, no gear clearance, high torque capacity, etc. It is widely used in various cutting-edge fields such as industrial robots, humanoid robots, semiconductor LCD production devices, photovoltaic equipment, optical instruments, precision machine tools, etc.

On January 1, 2006, Hammernaco and Nabtesco's US subsidiary established a joint venture company, Harmonic Drive L.L.C., in Massachusetts.

Basic Principles

In order to cover the low reduction ratio field that harmonic reducers cannot achieve, the product also involves precision planetary gearbox harmonic reducers. The unique deformation process of the inner ring gear can make the planetary gear mesh tighter and eliminate backlash, achieving precision transmission errors.

application area

Harmonic gear reducers are increasingly widely used in aerospace, energy, navigation and shipbuilding, biomimetic machinery, commonly used military equipment, machine tools and instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery, and medical equipment. Especially in high dynamic performance servo systems, harmonic gear transmission has shown its superiority. The fluctuation gears in the electric drive wheels of the Apollo lunar rover are products from Hamanaco~~

Thinking of the advertisement shot by Schaeffler bearings in Germany, without them, the world would have to stop spinning. So, without the Japanese, more than half of the robots, planes, and tanks around the world would have to lie down...

What Else Might You Learn?